For a high demand picking process, which can require up to 500 lines per hour per workstation, the Vertical Buffer Module is the ideal solution, since it operates under the "Good to person" principle; optimizing the fulfillment performance of small parts and light materials orders while ensuring high precision and high energy efficiency. A station can consist of one or more units.

High picking performance

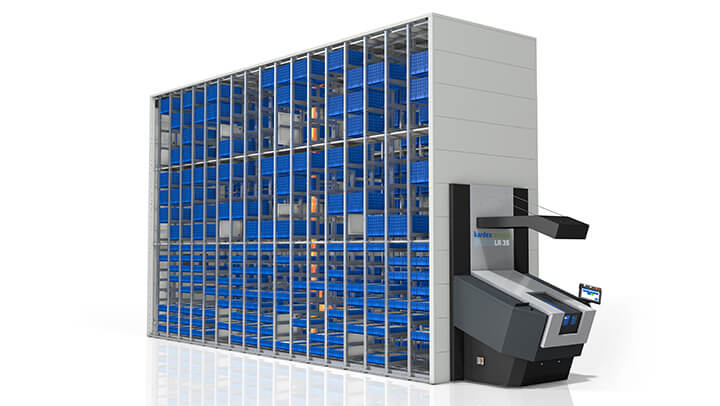

The Vertical Buffer Module LR35 is a highly efficient solution for storing and picking lightweight, small-volume items. Its high picking performance makes it suitable for use in many different areas.

The system significantly improves productivity and energy consumption, whether used to supply a production line for a wide range of products, such as buffering in the assembly area or slow picking of parts at distribution centers. In addition, high-value parts are much safer thanks to controlled access.

Energy efficiency and integration

The Vertical Buffer Module LR35 uses only a third of the energy of comparable systems. The use of the latest technologies and their innovative design features make this energy efficiency possible. Complex energy recovery is not necessary.

The Vertical Buffer Module can be flexibly incorporated into existing production systems and software, simplifying integration into current processes. A mix of cargo trays and containers holds up to four different heights within the Vertical Buffer Module LR35.

In addition to barcode scanners for asset identification and Pick to Light technology to increase picking speed and accuracy, the system can also be combined with existing transport systems and self-guided vehicles.

Ergonomics

The Vertical Buffer Module has ergonomically designed features at picking stations to simplify the order picking process. The elements are at 20-degree angle to the access opening to ensure that the box is always provided to the operator in an ergonomically optimal position. This ensures that the products can be easily retrieved or stored.

Items are transported to the picking station, according to the “Good to Person (GTP)” principle, to minimize the distance traveled by the operator. The cleverly thought-out design of the Vertical Buffer Module ensures sufficient space for the operator at all times.

Our specialized automatic storage department will guide you in the selection of the equipment that best meets your wishes and needs. Let G.I.Eicom* professionals help you add value, minimize costs, errors and space in your operation.

Horizontal carousels are good to person systems, combining, software, efficiency, and automatic storage for order fulfillment.

Read more

These systems are designed to save space and maximize assortment precision vertically within the item assortment area.

Read more

These are systems design to maximize assortment accuracy and save space in a vertical way.

Read more

They are born as support to the order assortment and are mainly used in systems that require great flexibility.

Read more

3D robotic order fulfillment system offering a highly flexible and scalable automated storage and retrieval solution.

Continuar leyendo